Improvement, Professional, Efficient

Our factory has the most advanced domestic production equipment and a series of independent transformation equipment, more than 1000 kinds of molds with different hole types, and takes customization as the development direction to provide corresponding product services to customers with different needs.

Complete Sets of Production Equipment

Production equipment is a key factor to measure the capacity of an enterprise. Yilida has complete sets of expanded metal production equipment and perforated metal production equipment.

From the raw material into production to the final surface treatment process, the whole process is strictly produced according to the standard to ensure that customers are provided with the highest quality products.

Diversified Surface Treatment Technologies

We have galvanizing, powder coating, anodizing, PVDF coating and other surface treatment technologies. As result, our expanded metal products not only enjoy an exceptional service life in terms of practical functions, but also deliver an amazing appearance in architectural decoration applications.

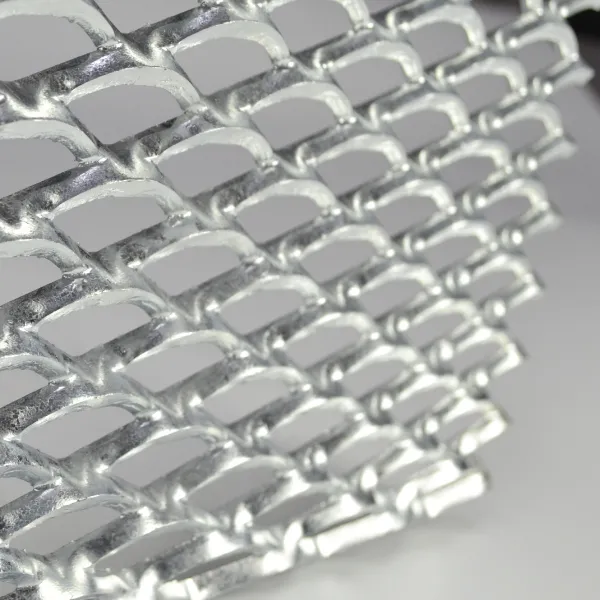

Galvanized Expanded Metal

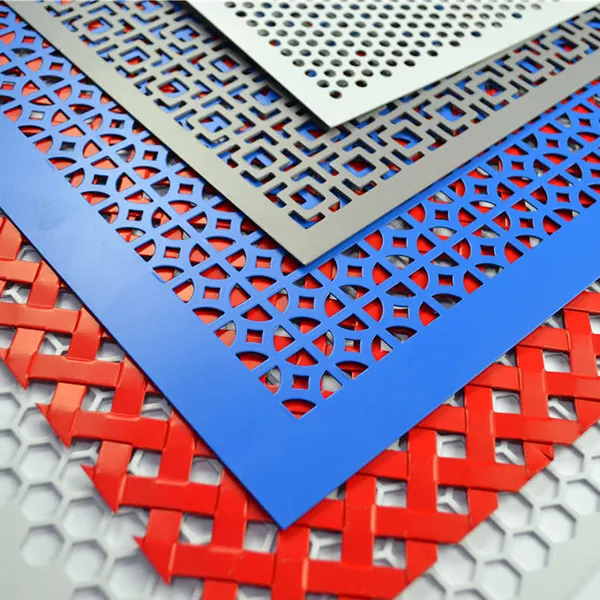

Powder Coated Perforated Metal Mesh

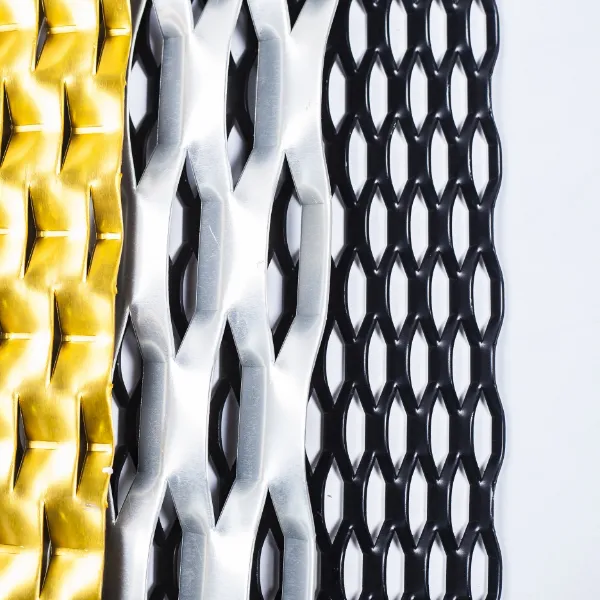

Anodized Expanded Metal

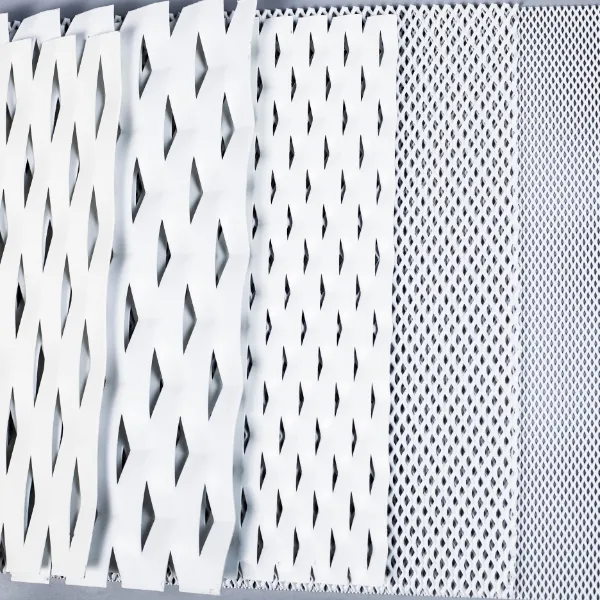

PVDF Coated Expanded Metal

Skilled Workers

Skilled Workers

Our operators and technicians are strictly trained and have many years of experience in manufacturing. They are familiar with every link in the production and can operate the automatic equipment skilfully.

Made-to-Order Service

Sometimes, our existing products may not perfectly meet your requirements. In this case, you may need our made-to-order service. we can provide proper suggestions according to your specific requirements, and develop customized products for you.

Raw Material

Carbon steel, galvanized steel, aluminum, copper and nickel plates for your option.

Punching Moulds

Over 500 kinds of punching moulds and new customized moulds are available.

Surface Treatment

Electrostatic powder coated anodized, PVDF coated surface treatment, etc.

Special Processing

U-shaped edging, bending, pleating and other forming processes.

E-mail: inquiry@wiremesh-yld.cn

Tel.: +86-13932824722

WhatsApp: +86-13932824722

Add.: Wire Mesh Development Zone, Anping, Hebei Province, China